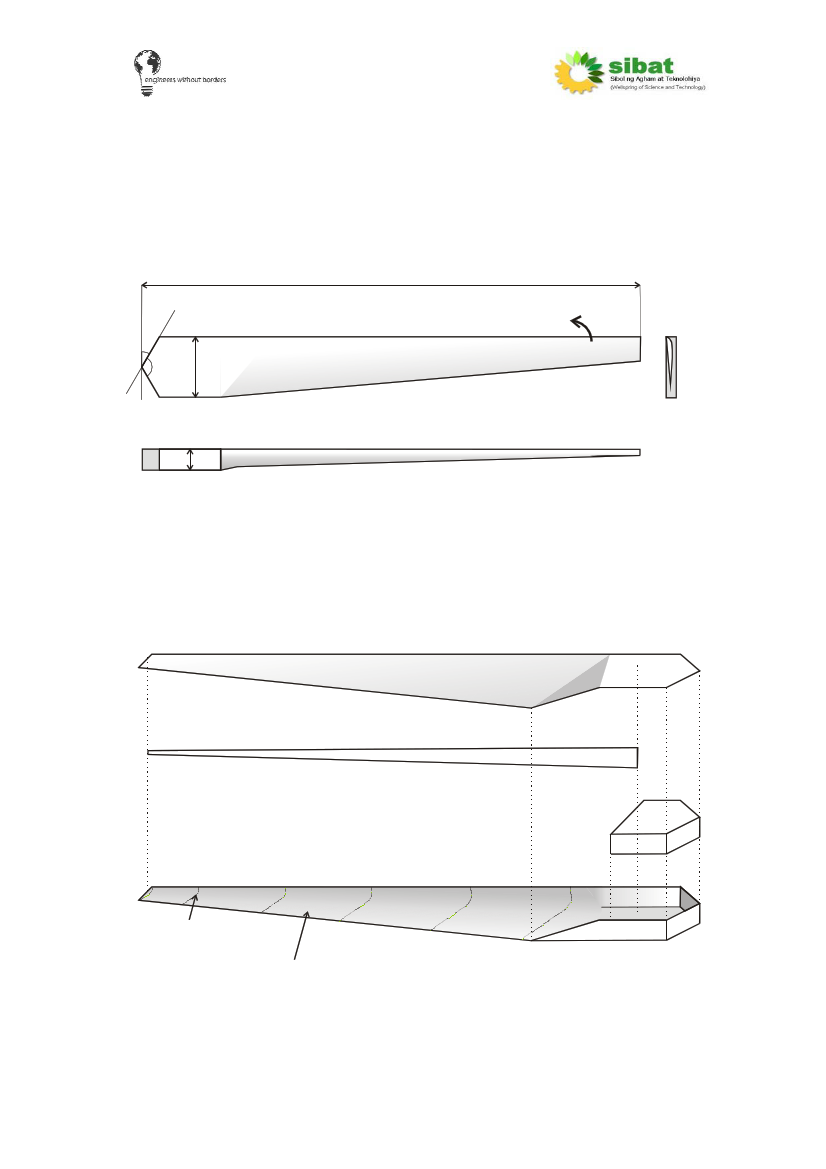

Basic Design

The basic blade shape is shown here. Please refer to ‘How to build a wind

turbine: the axial flux windmill plans’ for full details of the shape, curve and

size of the blade. This is the 6 foot (1kW) version of the wind turbine design.

Please note the definitions for Tip, Root, Leading edge, Trailing edge,

Stringer, Wooden core, Windward side, Backward side as these will be used

throughout this text.

View from front

30º (which faces the wind)

1.8m (6’)

Leading edge

Drawing not to scale

Blade rotational

direction

120º 20cm (8”)

Root

View from side

Trailing edge

Tip

View from tip end

5cm (2”)

The blade is comprised of two main halves (both made from fibre glass), a

wooden core at the root and a ‘stringer’ along the inside from root to tip. Once

the blade has been constructed and stuck together, a two-part expanding

foam is used to fill the structure of the blade helping to add strength and

rigidity to the blades.

“Exploded” view of blade construction

Windward side

Stringer

Wooden

core

These lines are just

to show curve of blade

Backward side

The space within the blade is filled with

two part expanding foam

5